Protecting the environment & managing resources

We continuously scrutinise boundary conditions and influencing factors and adjust our targets accordingly. A key cornerstone is the reference to scientifically sound and comprehensible parameters and processes. The collection of our data according to ESG criteria (environmental, social and governance) is in line with the classifications of the Greenhouse Gas Protocol (GHGP). We systematically identify potential for CO2e reduction and derive specific measures that we integrate into our continuous improvement process (PDCA cycle).

We record our greenhouse gas emissions separately in the areas of Scope 1 (direct emissions) and Scope 2 (indirect emissions). By 2026, we will also have further developed the recording of Scope 3 emissions. This will give us a comprehensive overview of our climate impact and enable us to take targeted reduction measures.

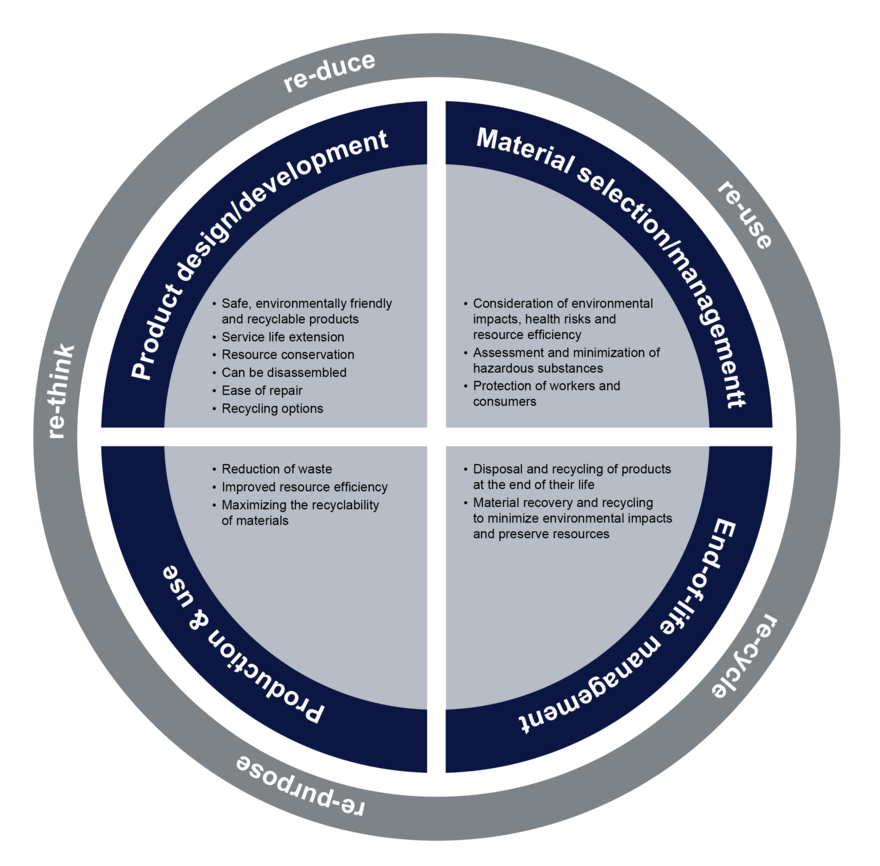

Circular economy

With the European Green Deal, the European Union has introduced a comprehensive strategy for sustainable growth and tackling climate change. As the AUNDE Group, we are doing our

contribution to achieving climate-neutral production of our automotive products. Key elements of this are a sustainable value chain, the development of circular product structures and the closing of material cycles, whereby we act according to the 5R principle:

- re-duce

- re-use

- re-cycle

- re-purpose

- re-think

Internationalization ensures competitiveness

At the AUNDE Group, one of the most important aspects of our work is that you can feel at home wherever you are. That is why, although we are based in Germany, our products, processes and production network are at home all over the world. We think globally and act locally, and we have predominantly local management teams in the various regions and countries. The AUNDE Group's business units mostly operate autonomously in their production networks, always taking the AUNDE Group's guidelines into account. Each business unit has its own headquarters, which is responsible for the respective production network and manages it centrally.

This is achieved primarily through regular coordination with the production sites, where key figures are reported and compared with the targets. In addition, new orders are placed by the headquarters with the production sites. These orders are implemented in close cooperation between headquarters and the production site. Standards and lessons learnt as well as local and customer requirements are taken into account. By continuously reviewing and adapting our production processes, we support the constant improvement of our efficiency and productivity.

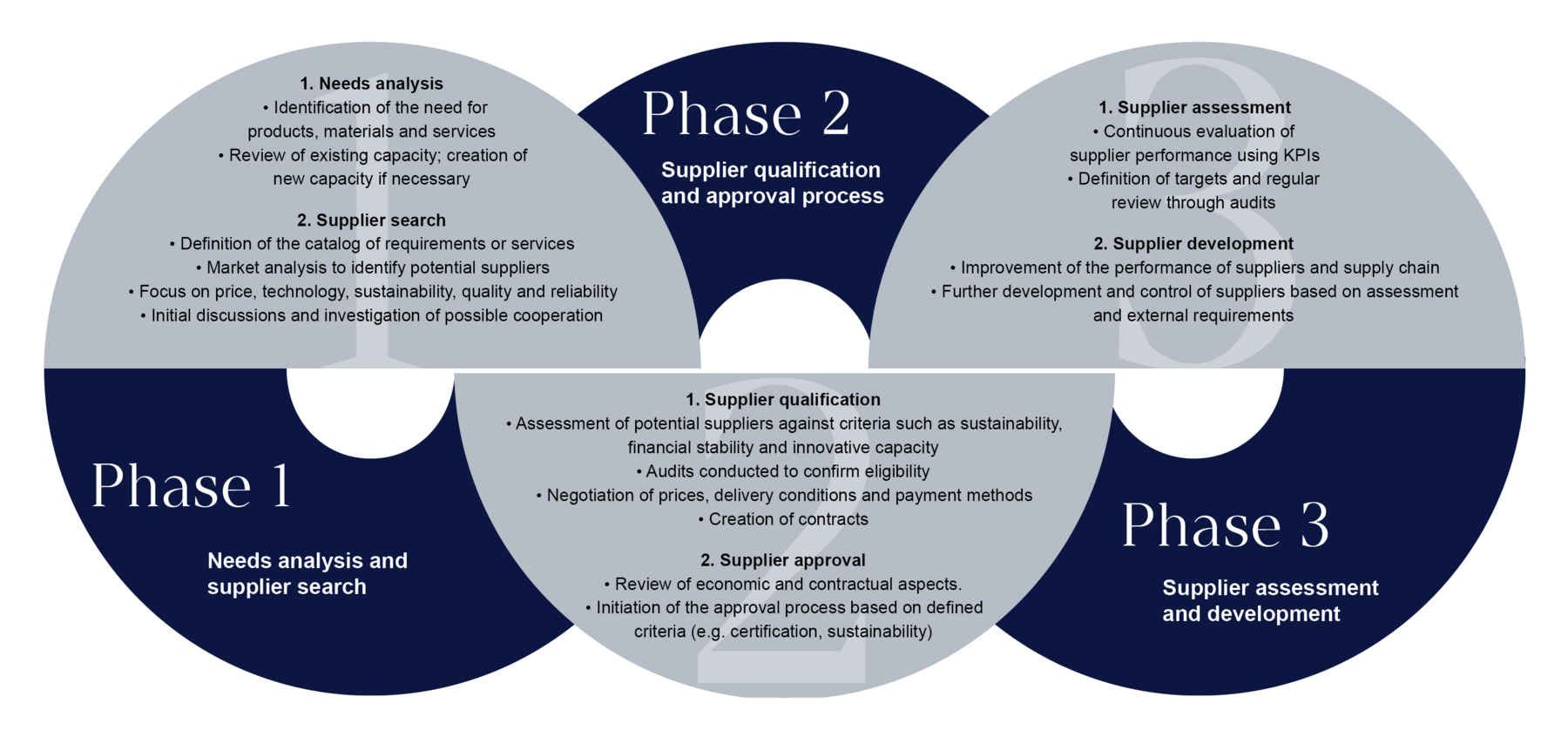

Holistic approach to the supply chain

The AUNDE Group is committed to sustainable supply chains by firmly integrating environmental and social standards into its purchasing guidelines. These measures promote transparent partnerships along the entire value chain. We attach great importance to loyalty, fairness and respect for the environment and people. A sustainable supply chain is central to our product quality and risk minimization. We use sustainable materials and maintain fair supplier relationships. We live sustainability and improve ecological and social conditions. As an international family business, we promote innovative, high-quality products and resource conservation. This strengthens our competitiveness and long-term stability. Our suppliers and employees are valuable assets, which is why trusting cooperation is crucial for us. Only through professional supply chain management can we ensure high quality and timely delivery. Our decentralized purchasing departments work closely with suppliers. A lead buyer organization bundles global procurement activities and thus supports a stable supply chain. This hybrid set-up enables us to achieve regional procurement in the procurement markets and manage our strategic partnerships at a local and global level. Digital supplier management in the AUNDE Group TIMS integrated management system supports efficiency and creates transparency across globally harmonized supplier processes, KPIs and structures.

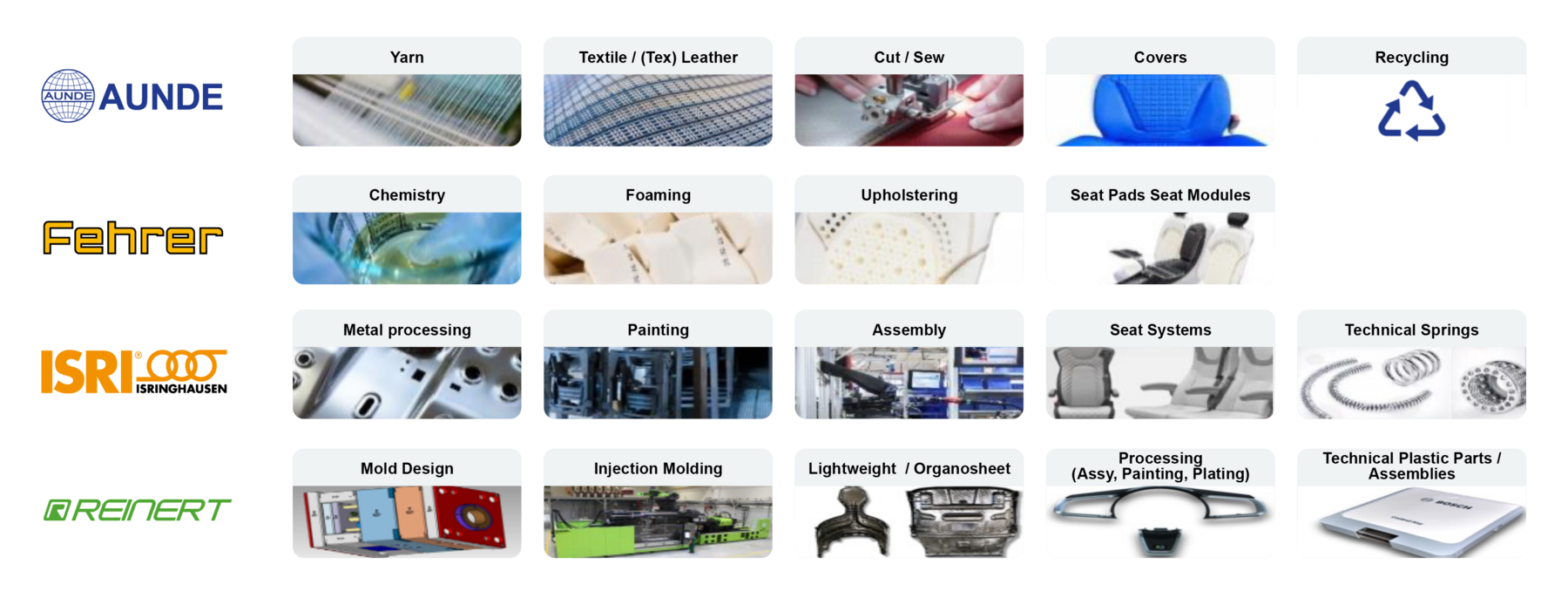

Vertical integration & added value

The AUNDE Group is characterised by remarkable vertical integration and high added value across all business units. An exemplary production chain for the manufacture of a lorry driver's seat begins in the AUNDE business unit with the production of the yarn from which the upholstery fabrics are woven, cut and sewn. The final assembly of the seat system also includes metal frames, springs and pneumatic components from ISRINGHAUSEN production, upholstery and foam components from FEHRER and plastic parts manufactured by REINERT. This vertical integration allows us to comprehensively control and manage the quality and efficiency of our products. Although the business units operate largely autonomously, synergy effects from material procurement and production to final assembly and delivery can be utilised by all AUNDE Group units.